Difference between revisions of "Molecular Dynamics Simulation of Aluminum Nanoparticles Sintering"

From Montana Tech High Performance Computing

| (5 intermediate revisions by the same user not shown) | |||

| Line 16: | Line 16: | ||

<div class="row"> | <div class="row"> | ||

<div class="large-6 column"> | <div class="large-6 column"> | ||

| − | [[File:Md_al1.png|600px]] | + | [[File:Md_al1.png|600px]][[File:Md8.png|600px]] |

</div> | </div> | ||

<div class="large-6 column"> | <div class="large-6 column"> | ||

| − | + | <youtube>_P2PT5BjktI</youtube><youtube>LCLQeSlxqEc</youtube> | |

</div> | </div> | ||

</div> | </div> | ||

Latest revision as of 16:10, 14 February 2018

Bowen Deng, David Hobbs, Bruce Madigan

Montana Tech

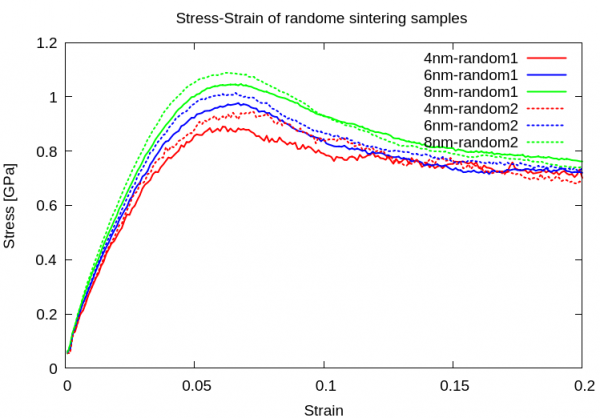

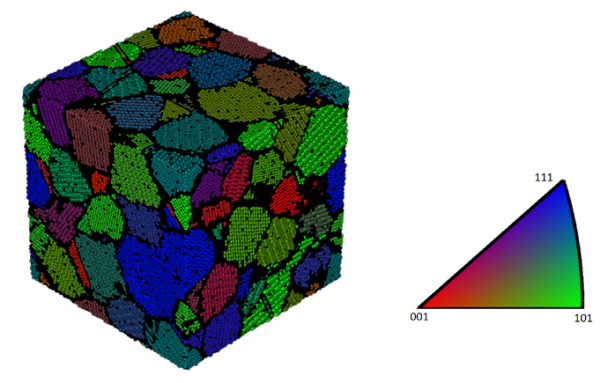

The selective laser sintering (SLS) process has attracted increasing interest as an additive manufacturing technique for metallic powder. In this study, molecular dynamics simulation is used to simulate SLS process and calculate mechanical properties of sintered aluminum nanoparticles. Various initial particle configurations that are more natural, as well as particle sizes and orientations are investigated and linked with the microstructures and mechanical properties of the sintered materials.